Still Cracks Me Up!

My excitement can turn to anticipation anxiety on most projects. In my mind I have a desire to have a Pit Fire built on my property. Initial thoughts were ‘dig a big hole’…

And then my Master Potter mentioned a basic setup involving a structure with a shaft (at ground level or thereabouts) to feed the fire.. I’ve seen a photo of one but questions remained… “Where to find the materials”, “How much is that going to cost”, “Can I find plans online”.. etc.

I did find a sense of relief and more excitement when I read this person’s blog recently – check it out! https://ellisonbaypottery.wordpress.com/pit-firing-at-ellison-bay-pottery/

www.facebook.com/1273380818/posts/10214612209080267

Ohmygoodness I love so much about this Bold Bear Coffee mug (and I love Coffee too lol) from the most recent wood-fire kiln firing. The handle Rocks especially the smooth glazed thumb rest placeholder. and the cute lil bear of course ❤️ it’s so big!

Excited to share this item from my #etsy shop: Bold Bear Handcrafted Woodfired Pottery Coffee Tea Mug Cup https://etsy.me/2Mb4BjB

Raku luminaries had a thick beginning! I had to cut a hole on top of three raku pieces and WOW I have more practice to do to get thinner bottoms.

Live and Learn

George Gasoigne

And the living is easy…..

Sounds like a plan right?!

Speaking of easy… I am currently in pottery class learning/doing alternate firing processes. We are going to be doing several different Raku firings, pit firing, barrel firing, soda something and ending with luster(ing?)… [still learning LOL]

Here is an example of one of the processes – this is called Naked Raku:

Naked Raku Orb by Charles and Linda Riggs, 2003. 7 in. (18 cm) in width. Stoneware painted with white terra sigillata and polished with a soft cloth, bisque fired to cone 010, covered in resist slip and glaze. Sgraffito through glaze before raku firing to 1400ºF (760°C).

I mentioned in earlier blogs that I ran into a ‘running of the glazes’ whilst using my favorite glaze combos. During the time of remedying the glaze issue I researched and found another glaze combo that a) allowed me to experience Testing of Tiles, and b) eventually produced an effect that is so juicy!

I had to lighten the photos a bit to help show the remarkable effects.

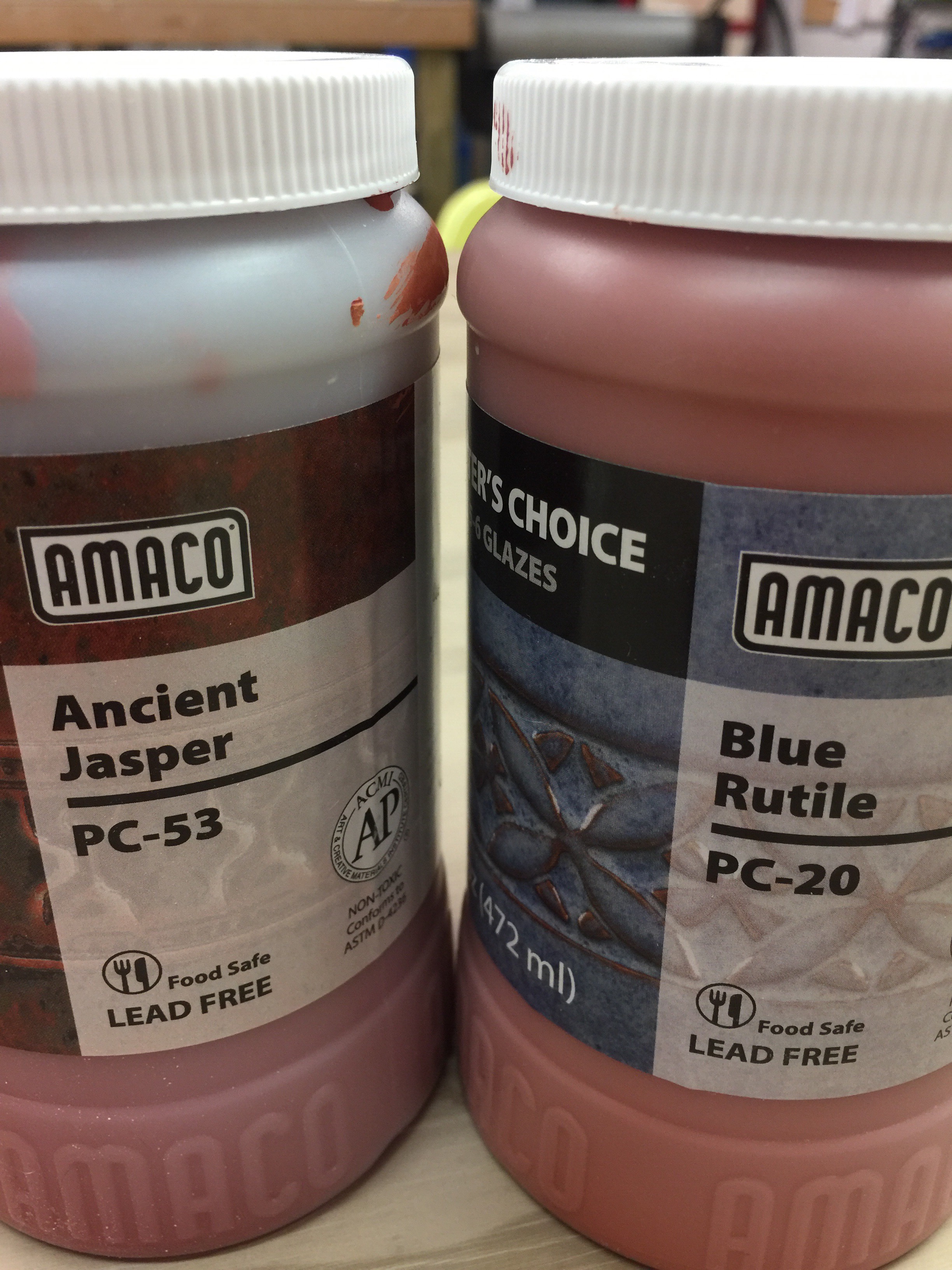

I used Amaco’s Potter’s Choice Glazes. Typically I first glazed 2x Obsidian Celadon, then 2x Merlot, then splashes of 2x Seaweed.

https://dirt-kickerpottery.blogspot.com/2016/02/magic-water-rocks-my-world.html

Magic water( 1 qt h20, 2. /14 tsp sodium silicate and 3/8 soda ash.)

How to Make and Use Magic Water https://www.marianwilliamspottery.com/2012/07/04/its-magical-how-to-make-and-use-magic-water/

First attempt to use brush-on glazes! To become familiar with the glazes, their combos, the running, as well as the processing in the studio kiln, I need to test the glaze on test tiles. So I made some. Well I gave it a try, rolled out some clay, texturized the slab, positioned the slab to dry… but I dried it too long so cutting the slab into little ‘test tiles’ became a chore. Anyhow I saved what I could I bisqued them, and wha-lah! LOL (the studio has an extruder and I was given the green light to use it – yeehaw!… I’ll document that experience in a later post after it happens).

The glazes I’m testing are Amaco’s Potter’s Choice: Ancient Jasper and Blue Rutile. After doing a lil research I LOVED results of using these two glazes that folks were posting.

I can’t believe I watched the whole thing from beginning to end and even replayed some parts! #Love #Pottery

Sometimes it’s a short walk through muck and mire, and other times not so much – but either way keep ahold of the bigger picture.

-SP Lascelles

These last few months have been attempts to rectify a running glaze issue using the same glaze combo and techniques that I’ve used for years. In this last couple batches I’ve had nice pieces go south. I was getting depressed.

So I’ve had opportunities to tweak:

During this time I didn’t have satisfactory results… as a matter-of-fact the running of the glazes produced another thorn to this potter’s experience because Kiln Shelves were affected, and that’s not a good thing. Especially more so because it was someone else (or a few people) who cleaned the shelves of the running glaze. Knowing the frustration and the hard work to clean glaze off a shelf I surely wasn’t happy to contribute to that.

I also had instances of cracking!

Experienced potters gave me suggestions and I am going to try them all. Here are the tips:

I really hope to find the happy place again, where my Cosmic Blue series can continue. However I am open to new illustrations of the celestial skies using different glaze combos that work well. Stay tuned for the updates!

I did acquire inspiration after researching a bit.

His page: http://www.campbellpottery.com/